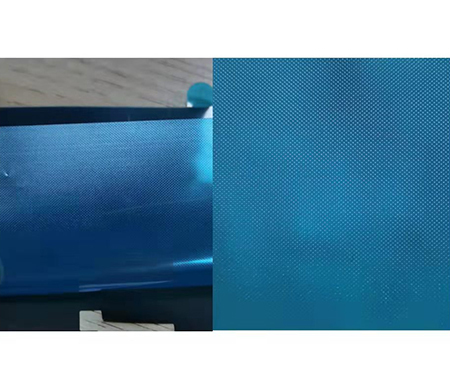

Blue Dot Mesh Silicone Protective Film

Blue Dot Mesh Silicone Protective Film

Blue Dot Mesh Silicone Protective Film

- 产品详情

The textured silicone protective film has a hemispherical dot pattern arranged at intervals, so that the contact area between the protective film and the product is relatively small after being bonded. The spacing between the two dots can facilitate effective alignment during bonding

。

Product performance:

1、High matching degree, wide range of use, the same protective film can be used for multiple materials 。 |

2、High cleanliness, which can reduce material damage |

3、Grid structure can disperse pressure and reduce direct damage from impurities and crystal points 。 |

4、 Easy to fit and peel off, which can improve the efficiency of automated assembly and reduce the defective rate 。 |

5、 It has an automatic air bubble discharge function. When inspecting the product, the protective film can be restored and can achieve the same effect as the equipment. |

Product usage: Foam, diffusion sheet, graphite sheet and other die-cutting process uses, as well as plastic shells, batteries and other surface protective films;

1. The die-cutting process supports waste discharge, stable quality, and more advantageous price; 50u transparent mesh 0 ~2,1~3g;

2. Diffusion sheet die-cut base;

3. Graphite sheets are die-cut and used as upper cover protective films. The assembled type is easy to peel off and the quality is more stable; these are mostly 50u, 75u blue, and the adhesion force can reach an ultra-narrow range of 0~0.8g, 0.8~1.5g, 1 ~2g, 2~3g, 3~5g;

4. Nanocrystal die-cut upper cover protective film;

5. Soft-pack battery surface protection;

6. The surface of the plastic shell is protected, easy to peel off without leaving any glue residue. Use 25u transparent 80~130g high-viscosity products.